Colloidal Graphite lubricant is a unique lubricant that offers a wide variety of benefits over other types of petroleum-based lubricants, in certain applications. Simply put, there are use cases in which colloidal graphite lubricant will outperform a petroleum lubricant.

If you are a manufacturer, an engineer, or a specialist in the nuclear industry, you are more than likely familiar with the differences between oil lubricants and Neolube, which is colloidal graphite suspended in isopropanol. The latter can be a timely and smart material to have in situations where a machine or part requires frequent disassembly and reassembly without damage to threaded connections.

How is Colloidal Graphite Lubricant different from Oil-based Lubricants?

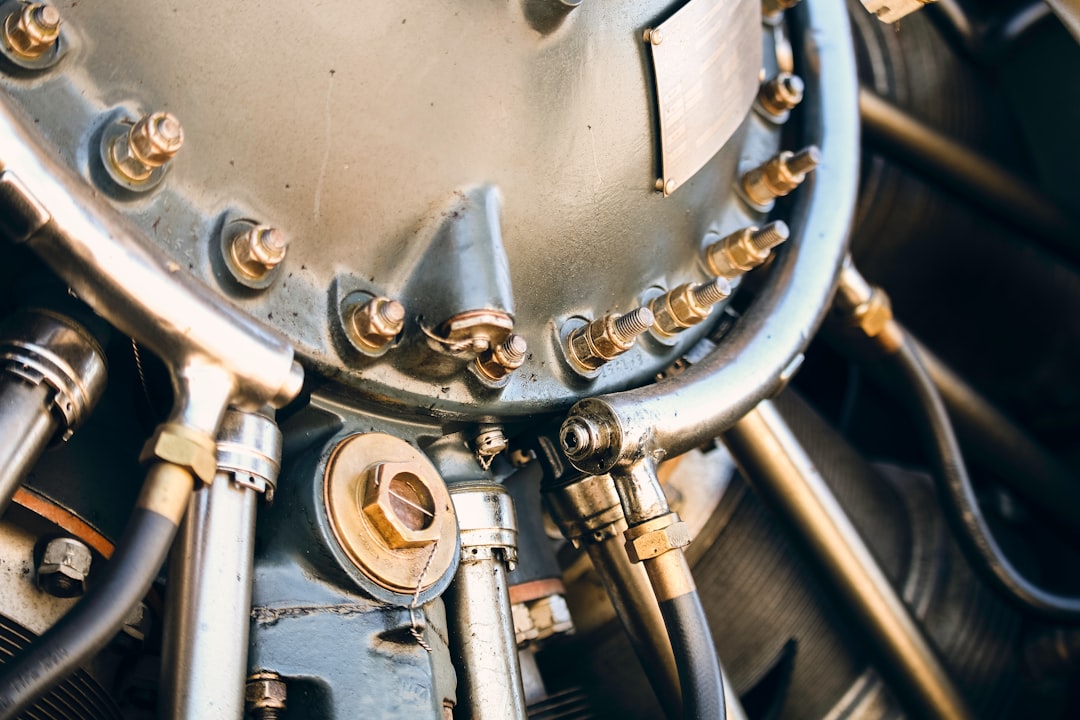

In many cases, oil-based lubricants are used to lubricate combustion engines for industry. This is mostly due to the requirements of high-speed moving parts and the low cost of oil-based lubricants.

However, these oil-based products have severe limitations where dry-film lubricants are better suited. Grease disadvantages are grease-life limitations and limited cooling ability. Also, in some instances, there is a risk of grease starvation, which results in reduced lubrication.

That’s why as a manufacturer it is important to choose a lubricant that fits the environment for which it will be used. Graphite as a lubricant is in wide use in several industries including manufacturing, industrial, aerospace, and nuclear. More specifically, it is used in high-temperature settings, pressurized systems, and dusty environments where oil-based lubricants often fail.

What are the benefits of using a Colloidal Graphite Lubricant?

Colloidal Graphite Lubricant is Effective in High Temperatures

Graphite is best suited for lubrication in air. A liquid, much like isopropanol is a necessary component for graphite lubrication. When water is absorbed, it reduces the bonding energy of the graphite to a lower level. Thus, water vapor becomes a necessity for proper lubrication. Graphite powder on its own is not effective.

Another benefit of colloidal graphite lubricant is that it is highly effective in high temperatures. The effectiveness of graphite can reach high temperatures up to 450 °C, with a possibility of reaching even higher temperatures, continuously testing higher temperature peaks.

Colloidal Graphite Prevents Galling

Graphite is also effective in preventing galling. When metal surfaces undergo a combination of sliding, excessive force, and high friction, galling can occur. In essence, galling is the transfer of metal and other materials between two surfaces. Over time this tends to cause damage to those metals and machines. Graphite as a lubricant can help this deterioration from occurring. Through a simple wipe-on of the best dry graphite-based lubricants, galling can be prevented.

Colloidal Graphite Lubricant is Easy To Use and Simple to Apply

The beauty of colloidal graphite lubricant is that it leaves no mess, and no contamination lubricant is needed. Wet lubricants tend to dry up, oftentimes becoming gummy, making it even more difficult for you to operate your equipment. Wet lubricants also have the tendency to attract other unwanted particles, like dust or sand, which again obstructs your equipment, and hinders your use of it.

Graphite is hydrophobic, meaning it naturally repels water, so you need not worry about the sticky situation that you face with other lubricants. It won’t harm your machines or create an unwanted residue after. It’s easy to use and can be applied via a wet or dry solution.

The Bottom Line about Colloidal Graphite Lubricant

With all that being said, colloidal graphite lubricant poses a positive substitute for the alternative lubricant options available in the market. A manufacturer or any other professional in aerospace, industrial, nuclear, or any other industry for that matter, graphite as a dry lubricant serves as a viable option and replacement.

Colloidal Graphite lubricant is a great option for any manufacturing company that is looking for ways to eliminate damage to threaded connections during assembly and/or maintenance of expensive machines in high-temperature, high-pressure, or dusty industrial settings.

If you’d like to learn more about our colloidal graphite lubricant, NEOLUBE product line, and how it can fit your needs, talk to our colloidal graphite lubricant expert, today.